Li-Metal becomes one of the first technology developers and advanced

battery material suppliers to successfully reprocess anode scrap material

into metal ingots suitable for foil production

Li-Metal commissions lithium metal reprocessing and casting facility in

Markham, Ontario, which has the capacity to process up to 15 metric tonnes

of anode scrap material per year

Validates a key component of modular, patented C2M technology and

strengthens ability to deliver sustainable lithium metal solutions for

next-generation battery anodes

TORONTO, Canada, November 8, 2023 – Li-Metal Corp. (CSE: LIM) (OTCQB: LIMFF) (FSE: 5ZO)

(“Li-Metal” or the “Company”), a developer of lithium metal anode and lithium

metal production technologies critical for next-generation batteries, today

announced the successful production and shipment of its first batch of lithium

metal ingots. The lithium metal ingots were produced at Li-Metal’s recently

commissioned lithium metal reprocessing and casting facility in Markham,

Ontario, which has the capacity to process up to 15 metric tonnes of anode

scrap material per year.

Lithium metal anodes are produced either through a conventional

extrusion/rolling or through more economically viable physical vapor

deposition (PVD) processes, the commercialization of which Li-Metal is

championing in conjunction with its exclusive manufacturing partner, Mustang

Vacuum Systems. Traditional extrusion processes require the lithium metal to

be supplied in ingot form. On average, production scrap generated by

gigafactories can have up to a 30% metal scrap rate.[i]

Lithium metal ingot manufacturing scraps are currently designated as hazardous

waste and, typically, incinerated whereby valuable, critical battery materials

are lost forever.

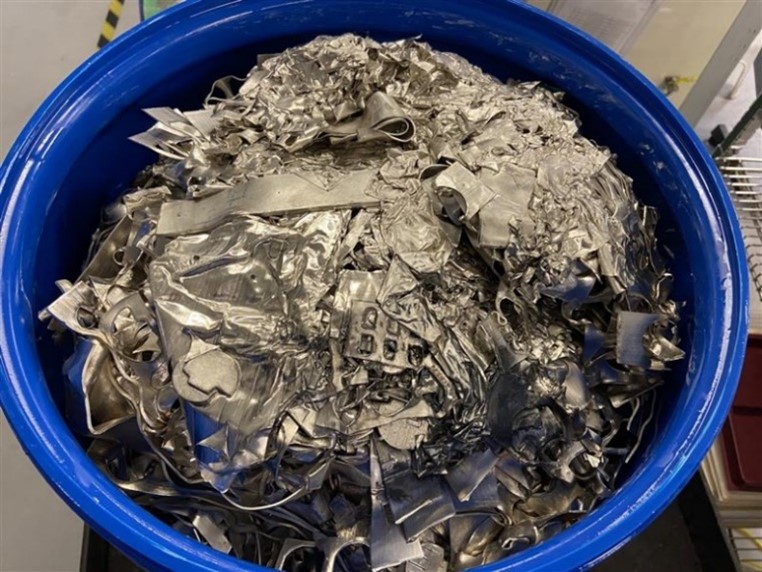

To enhance the sustainability of lithium metal anodes and to overcome the need

to incinerate scrap lithium metal, Li-Metal developed a novel reprocessing and

casting technology. The Company’s technology reprocesses the scrap lithium

into ingots that may be used for anode production. The lithium metal ingot

(seen in the image), a large solid block of metal, was produced using lithium

material from production scrap from lithium foil producers. As Li-Metal

continues to progress with its lithium metal reprocessing program and

demonstrating the continuous production of lithium metal ingots, the Company

is currently evaluating scrap samples from multiple partners to scale

capacity. Li-Metal expects to eventually leverage the pilot facility and

know-how generated during the scale up of the reprocessing facility to help

its potential partners produce high purity specialty lithium-alloy ingots for

advanced battery producers.

“We are thrilled to produce our first batch of lithium metal ingots using our

reprocessing and casting technology and commission our new facility in

Markham,” said Srini Godavarthy, CEO of Li-Metal. “The ability to produce

lithium metal products is a key differentiator for Li-Metal’s positioning in

the next-generation battery ecosystem, further enabling the growth and

development of our business. This is an important milestone in our roadmap as

we advance our technologies and plan to become a leading vertically integrated

and domestic supplier of lithium metal and high-performance anode materials.”

Earlier this year, Li-Metal successfully produced its first lithium metal

product using its patented carbonate to metal (C2M) technology at its lithium

metal pilot facility in Markham, Ontario. Li-Metal’s C2M technology was named

one of TIME's Best Inventions of 2023. The Company’s C2M technology is

designed to produce high-quality lithium metal ingots with the lowest

environmental footprint globally. The additional capabilities to produce

lithium metal ingots from scrap allows for diversity of raw material supply,

which is critical as the Company continues to advance its C2M metal technology

and its ultra-thin lithium metal anodes platform.

Conventional lithium-ion batteries, while widely used, face critical

challenges including limited energy density, slow charging, capacity fade and

safety concerns that hinder their ability to meet the evolving demands of our

modern world.[ii]

To overcome these challenges next-generation battery technologies that replace

graphite anodes with lithium metal are being developed. The scale up of these

technologies by 2028-2030 is expected to deliver compact and high-capacity

power sources that could unlock new markets, including electric aviation and

eVTOLs, in addition to mitigating electric vehicle range anxiety and making

them more cost efficient.[iii]

In line with the scale up, Li-Metal is advancing its vertically integrated

lithium metal and anode technology platform to produce ultra-thin,

high-performance lithium metal anodes to help enable the commercialization of

next-generation battery technologies.

Image (left): Lithium metal scrap material

Image (right): Lithium metal ingot produced with scrap lithium metal material

Li-Metal also announced that it has signed a digital marketing agreement,

which is expected to start on or around November 15, 2023, retaining

Aktiencheck AG (the “Service Provider”) located at Bahnhofstrasse 6, 56470

Bad Marienberg, Germany (email: stefan.lindam@aktiencheck.de), to provide

marketing services to the Company. Aktiencheck AG has been engaged to

heighten investor awareness for the Company by providing digital content,

advertising and promotional services targeting the European market.

Aktiencheck AG will provide these services for a two-month period (ending

mid-January 2024), for which Li-Metal has agreed to pay US$200,000. Services

provided pursuant to the agreement will include media placements and

distribution of original content, including articles and advertisements, to

be distributed via various investment portals. The Service Provider will

also update the European market on latest Company developments and provide

digital advertising consulting services. Neither the principals nor any

employees of the Service Provider hold common shares, options or warrants of

Li-Metal.

ON BEHALF OF THE BOARD

Srini Godavarthy

Chief Executive Officer

About Li-Metal Corp.

Li-Metal is a Canadian-based vertically integrated battery materials company

and innovator commercializing technologies to enable next-generation batteries

for electric vehicles and other applications. We believe our patented lithium

metal technology, which was recognized on the TIME best innovations list for

2023,[iv]

and next-generation battery anode technology and production methods are

significantly more sustainable than existing solutions and offer lighter, more

energy-dense and safer batteries. Li-Metal's battery materials support battery

developers' ability to power more cost-effective electric vehicles that go

farther and unlock the future of transportation. For more information, visit:

www.li-metal.com.

Forward-Looking Information

This news release contains "forward-looking information" within the meaning of

applicable securities laws relating to the Company. Any such forward-looking

statements may be identified by words such as "expects", "anticipates",

"believes", "projects", "plans" and similar expressions. Readers are cautioned

not to place undue reliance on forward-looking statements. Statements about,

among other things, the Company's strategic plans are forward-looking

information. These statements should not be read as guarantees of future

performance or results. Such statements involve known and unknown risks,

uncertainties and other factors that may cause actual results, performance or

achievements to be materially different from those implied by such statements.

Although such statements are based on management's reasonable assumptions,

there can be no assurance that the development of the business of the Company

will be completed as described above. The Company assumes no responsibility to

update or revise forward-looking information to reflect new events or

circumstances unless required by applicable law.

Li-Metal Investor Contact:

Salisha Ilyas

ir@li-metal.com

Tel: +1 647 494 4887

Li-Metal Media Contact:

Harry Nicholas

Li-MetalPR@icrinc.com

[i]

https://www.fastmarkets.com/insights/six-key-trends-battery-recycling-market/

[iii]

Benchmark Mineral Intelligence: Solid-state and lithium metal batteries

2023 technology handbook

[iv]

https://time.com/collection/best-inventions-2023/